News

Aluminum RIB Boat Production Process

Yoolwin Boat can produce with different usages aluminum rigid RIB Boats, military and patrol/ rescue and search/ leisure and water sports/ dinghy and tender inflatable rib aluminum boat. Size from 3m to 11m. Each boat size with different boat models, designed with open/ sport/ luxury models. Yoolwin Boat also with professional engineer, can design the hull inside structure and boat layout according to customer demand. Also test boat with best performance (stability/ durability/ speed).

1. Boat structure and layout design

Each aluminum rib boat tube color/ hull color/ seat cushions color and EVA color can change as demand. Boat structure can also design as demand. Optional accessories, such as fishing rod holder/ fridge/ electric toilet/ hand washing/ shower system etc. Can all equip as customer demand and boat structure. Yoolwin China factory have own engineer, also cooperate with Italy popular boat designer. Can supply two lines of aluminum rigid boats. Different from boat sailing speed and production details.

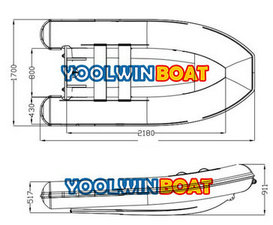

3.6m aluminum sport rib boat open model:

2. Aluminum Hull Material Preparing:

According to aluminum rigid rib boats design and structure, can cut the aluminum hull material. All Yoolwin Boat aluminum hull made from aluminum 5083 by CCS, marine grade, so we can get popular during the government and patrol usage aluminum rhib boats. With CNC (Computer Numerical Control) cutting machine, boat aluminum material can be cut with better precision. Cut the boat different parts for hull/ inside structure keel/ transom/ console/ driver seat/ front and back cabin.

3. Aluminum Material Welding

Aluminum rib inflatable boat hull welding as one critical process during whole boat production. This will much influent the whole boat strength. Yoolwin boat welding worker with more than 10 years production experience. Boat welding parts keep smooth and flat, so with better durablity and good outside appearance show the boat quality. Specially for the welding joints, this will much skill the workers experience.

4. Whole boat aluminum hull production

After all parts finished, deep v double aluminum hull, inside structure and keep, then aluminum hull stucture can be totally finished. Inside also can equipped with build-in fuel tank and water tank. Skilled workers will finish the aluminum hull parts with following attention points: welding temperature and welding speed.

5. Aluminum hull power coating

Aluminum hull should totally clean first, water clean as the first step, delete the appearance dirt and oils. Acid - based etchant or an aluminum - specific surface treatment solution as an importance process for the aluminum hull power coating, this can reducenatural oxide layer on its surface. Protect the surface and inhance the adhension. Power painting inside the special painting room, can do with different colors, most popular for white/ gray/ black. If prefer with other colors, can also contact us to confirm before placing the order. Final curving enhance the power painting on the aluminum hull.

6. Tube making

Tube can do with different tube material. Check our before arcital how to choose the suitable tube material for aluminum rib boat. PVC/ Hypalon/ Orca Hypalon. Color also can do as demand. Color design and logo design also accepted before the boat production. With accessories for different air chambers, inflate/ deflate valves and safety valves. According to the boat stern with platform or not, can choose with shark model tube ends or round models.

7. Optional accessories install as demand

Luxury aluminum ribs normally equipped with electric toilet/ hand washing/ shower system. Elctrics for marine stereo, electric windlass, GPS, radar, VHF etc. Logo can also do with customers. But for smaller aluminum rhibs normally for fishing rod holder/ bimini sun shade/ cup holders/ small trailer etc.

RELATED NEWS

- Aluminum Rib Military Navy Boat Maintenance Guide 2025-04-12

- How to choose the suitable engine for inflatable boats: Comprehensive Analysis 2025-04-08

- Enhance Your 960 Cabin Luxury RIB Boats Experience: A Guide to Optional Accessor 2025-04-02

- How to choose suitable floor for inflatable motor boat: Comprehensive analysis 2025-03-30

- Select ideal tube material for Rigid Aluminum Boats: Comprehensive analysis for 2025-03-23

CATEGORIES

LATEST NEWS

CONTACT US

Contact: Grace

Phone: +86-15966910461

E-mail: grace@yoolwin.com

Whatsapp:+86-15966910461

Add: Chengyang district, Qingdao city, Shandong Province, China